Industrial borescopes have become a core inspection tool across aviation maintenance, repair, and overhaul. They help technicians and inspectors evaluate internal conditions without unnecessary disassembly, saving time while supporting consistent documentation. Whether the task involves turbine blades, gearboxes, structural cavities, or fluid lines, a well-matched borescope can provide the visual access needed to make confident decisions.

In the broader inspection equipment market, companies like USA Borescopes offer borescope and videoscope solutions that support remote visual inspection needs across aerospace and other demanding industries.

The main categories of borescopes used in aerospace

Not all borescopes are built the same. Aerospace teams typically choose from a few major categories based on access constraints, image requirements, and the method of documentation.

Rigid borescopes

Rigid borescopes are straight, non-flexible optical tools often used when access is relatively direct. They can deliver sharp images in controlled conditions and are commonly selected for inspections where a straight path exists and the inspection area is stable and predictable.

Common use cases include:

- Straight-line access ports on certain assemblies

- Bench inspections where components are positioned for direct viewing

- Situations where durability and simplicity are priorities

Rigid scopes can be excellent when they fit the geometry, but they are limited when the route requires bends or when the inspection target is around a corner.

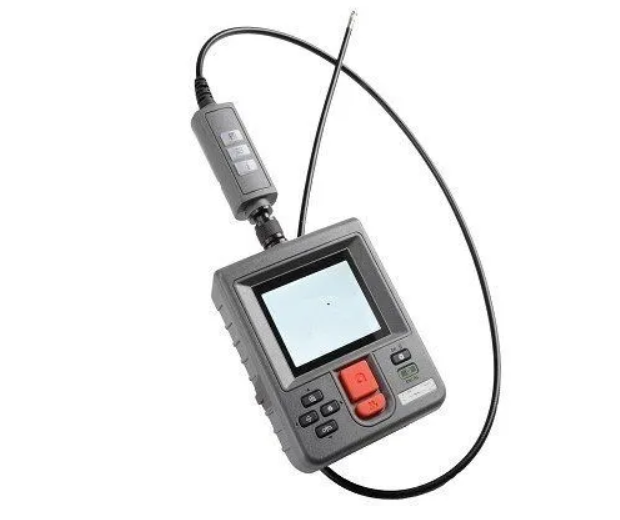

Flexible videoscopes and fiberscopes

Flexible scopes are designed for real-world access challenges. They allow technicians to navigate bends, route around obstructions, and reach deeper into confined areas. In aerospace, flexible scopes are often the default choice because many inspection points are not straight-line accessible.

Within flexible options, two common types appear:

- Videoscopes, which use a camera at the tip and display images digitally

- Fiberscopes, which transmit an image through fiber bundles

Modern aviation operations often lean toward videoscopes due to their ability to record images and video, support clearer documentation, and provide easier sharing of findings across teams.

Imaging fundamentals that matter in real inspections

In aerospace inspections, image quality is not a nice-to-have. It affects decision-making. A clear image can reduce debate, minimize re-inspections, and improve confidence in repair planning.

Key imaging fundamentals include:

- Resolution and clarity

Higher resolution can help, but clarity is also driven by lighting, sensor performance, and stability. An image that is technically high resolution but full of glare or motion blur is not helpful. - Lighting control

Internal surfaces can be reflective, dark, or uneven. Adjustable lighting helps reduce glare and reveal surface features more consistently. - Color accuracy and contrast

Surface discoloration, heat tint, and residue can be meaningful. Strong contrast helps technicians distinguish a true defect from film, staining, or reflections. - Consistency across inspections

Repeatable imaging supports trending. If images look significantly different each time due to poor lighting control or inconsistent technique, comparison becomes less reliable.

In practice, teams benefit most when the tool helps them capture repeatable evidence that others can interpret quickly.

Articulation and probe control options

Articulation refers to how the probe tip can be steered to look around corners and cover more surface area without withdrawing and reinserting. In aerospace, articulation impacts both inspection coverage and inspection time.

Common control considerations include:

- Two-way versus four-way articulation

Two-way articulation steers in a single plane. Four-way articulation allows up, down, left, and right movement, which is useful in complex geometries. - Responsiveness and fine control

Some inspections require subtle adjustments to confirm a feature or reduce glare. Fine control helps keep images stable and reduces operator fatigue. - Probe stiffness and handling

A probe that is too flexible may be difficult to push through certain routes. A probe that is too stiff may struggle to navigate tight bends. The best balance depends on the access path.

When articulation matches the inspection environment, technicians can cover more area in less time and reduce repeated insertions that add wear and risk.

Viewing direction and field coverage

Viewing direction influences what the operator can see without repositioning. Aerospace inspections often require both forward viewing to navigate and side viewing to examine surfaces.

Common viewing configurations include:

- Forward view

Useful for navigation and for features directly ahead of the probe tip. - Side view

Useful for inspecting walls, internal surfaces, and areas adjacent to the route. - Dual view

Useful for reducing probe repositioning. Switching between perspectives can help confirm an indication and build stronger evidence.

The field of view also matters. A wider field of view can help with situational awareness and broader scanning. A narrower field of view can support detailed work in specific zones. In many real inspections, technicians use a mix of distance and angle rather than relying on zoom alone.

Measurement and advanced inspection capabilities

Many aerospace teams want more than a visual check. They want evidence that supports defect monitoring and repair decisions. Measurement capabilities vary by system and are heavily dependent on technique and training.

Common measurement and analysis capabilities include:

- Basic on-screen reference tools

Useful for simple comparisons and quick communication, but limited for precise sizing. - Measurement systems designed for defect sizing

Some video scopes support measurement tools to estimate size, depth, or area. These can help when documenting progression or supporting decision pathways, especially when consistent methodology is used. - 3D measurement and stereo measurement approaches

Some systems support methods that help approximate dimensions more reliably, particularly when the operator captures the image correctly and follows the proper process.

Even with advanced tools, measurement should be treated as part of an overall inspection process. Angle, distance, and surface reflectivity can influence results. Teams that get the best outcomes typically standardize how measurements are captured, recorded, and reviewed.

Typical aerospace applications for industrial borescopes

Industrial borescopes appear across many inspection tasks. The exact scope and method depend on access, component type, and inspection criteria, but common applications include:

- Turbine engine inspections

Compressor sections, combustion areas, turbine blades, and internal flow paths are common targets for borescope inspection. A good scope supports stable imaging, controlled lighting, and repeatable documentation. - Auxiliary power units and accessory systems

Compact assemblies often benefit from flexible probes and strong articulation. - Gearboxes and mechanical housings

Inspections may require side viewing to evaluate surfaces and internal features. - Structural cavities and airframe access areas

Borescopes support inspections in tight internal spaces where line of sight is not possible. - Fluid lines, ducting, and internal routing areas

Flexible scopes can navigate bends and confirm internal conditions without disassembly.

Across these use cases, the most effective tools are the ones that match the physical access route and produce evidence others can review without needing a repeat inspection.

Procurement considerations for aviation teams

Selecting a borescope in aerospace is not just about specs. It is about being fit for the tasks that occur repeatedly and the workflow that surrounds inspection evidence.

Common procurement considerations include:

- Access requirements

Probe diameter, working length, and bend tolerance should align with real access points. - Usability and training

The system should support consistent results across technicians with different experience levels. - Durability and serviceability

Aerospace environments require rugged handling. Repair options, turnaround time, and support access can matter as much as initial performance. - Documentation workflow

Images and video should be easy to capture, label, store, and share. A tool that creates great images but complicates retrieval can slow down the overall process. - Accessories and attachments

Certain applications may require protective options, guide tubes, or specialized tips depending on the environment.

For teams comparing equipment options, USA Borescopes products provide a starting point for reviewing different inspection configurations and capabilities.

Industrial borescopes support aerospace maintenance by making internal inspections faster, more consistent, and easier to document. Understanding the main tool categories, image fundamentals, articulation options, viewing configurations, and measurement capabilities helps teams choose equipment that fits real access challenges. The right selection reduces re-inspections, improves evidence quality, and supports better decision-making across technicians, leads, and QA.

For organizations evaluating inspection equipment, USA Borescopes provides inspection solutions and support services designed for demanding use cases. For guidance on selecting a borescope for aviation applications or to discuss an inspection requirement, reach out to their team via the contact page.

About The Author

The author is an independent inspection technology specialist with experience advising maintenance and reliability teams on remote visual inspection practices. Their work focuses on selecting the right inspection tools, improving evidence quality, and standardizing workflows for repeatable results.